Automatic Roll Air Filters for Oil and Gas Compressor Stations – Reliable Filtration for Harsh Industrial Environments

Oil and gas compressor stations operate under extreme environmental conditions where dust, sand, and oil mist can compromise equipment performance and increase maintenance costs. Contaminants in intake air not only reduce compressor efficiency but also accelerate wear on turbines, engines, and filtration systems. To meet these challenges, the Automatic Roll Air Filter from HICLOVER provides a high-performance, low-maintenance solution for continuous air purification in compressor stations, gas processing facilities, and pipeline booster stations across North America and global industrial sites.

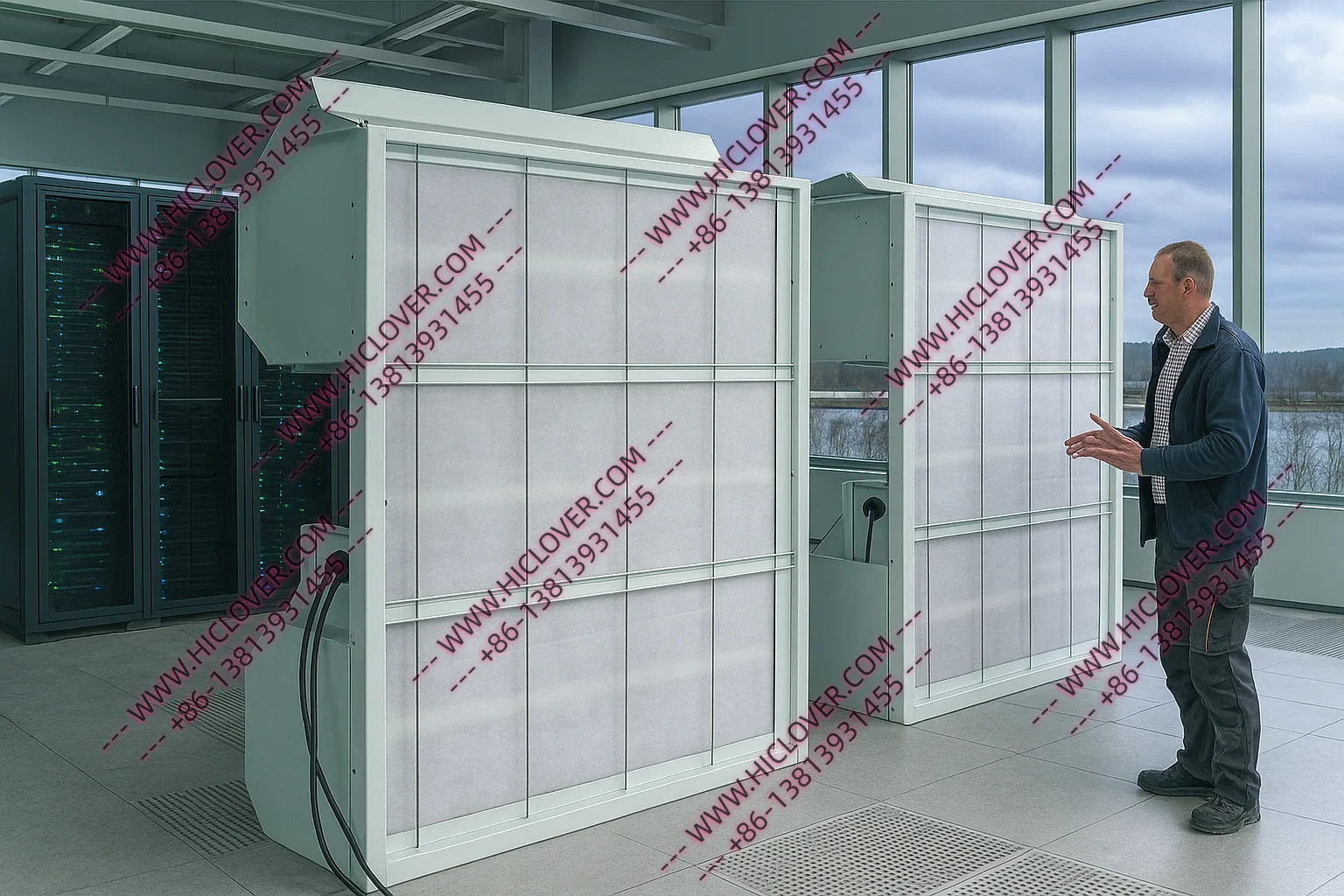

Advanced Filtration for Industrial Air Intake Systems

Conventional filters require manual replacement, creating downtime and exposing operators to contaminated air. The Automatic Roll Air Filter eliminates this problem with a PLC-controlled automatic media replacement system, which continuously unwinds a fresh filter sheet while rolling the used material onto a collection reel.

Key benefits include:

-

Automatic filter media replacement triggered by differential pressure sensors.

-

Continuous airflow for stable compressor performance and reduced system strain.

-

Lower labor costs and minimal downtime through fully automated operation.

-

Efficient removal of oil mist and particulate matter, improving air quality in engine rooms and compressor enclosures.

Engineered for Harsh Environments

The Automatic Roll Air Filter is built to withstand demanding conditions common in oil fields, gas compression stations, and offshore platforms.

Its heavy-duty galvanized or stainless-steel housing resists corrosion from salt-laden air and hydrocarbon vapors.

Reinforced drive motors ensure uninterrupted operation in dusty or humid climates.

When combined with secondary filtration systems — such as coalescing filters or HEPA backup units — the HICLOVER system provides comprehensive protection for compressor intakes, control rooms, and turbine enclosures.

Energy Efficiency and Intelligent Control

Maintaining proper airflow across compressors is critical for energy efficiency. The Automatic Roll Air Filter automatically advances when resistance reaches a preset threshold, preventing airflow restriction and optimizing power consumption.

Integrated smart PLC logic allows remote monitoring and connection to SCADA or Building Management Systems (BMS) for automated maintenance scheduling and performance tracking.

To explore product details or integration options, visit CloverFilter Industrial Air Solutions or CloverFilter Automation Systems.

Why Choose HICLOVER

HICLOVER designs its automatic air filtration systems for continuous-duty industrial applications.

With installations serving the oil, gas, and energy sectors, each Automatic Roll Air Filter combines mechanical durability, automated efficiency, and compliance with EPA and OSHA air quality standards.

The result is a reliable filtration solution that extends equipment life, enhances system safety, and reduces operating costs.

Contact:

Email: [email protected]

Website: www.cloverfilter.com

Mobile/WhatsApp: +86-13813931455

Resumen en Español (México)

En las estaciones compresoras de gas y petróleo en México, el polvo del desierto y el rocío de aceite reducen la eficiencia de los equipos. Los Filtros Automáticos de Aire con Enrollado de HICLOVER ofrecen un sistema totalmente automatizado que reemplaza el medio filtrante sin detener la operación, manteniendo un flujo de aire constante y limpio.

Diseñados para ambientes industriales severos, estos filtros reducen el mantenimiento, mejoran la eficiencia energética y cumplen con las normas ambientales mexicanas y norteamericanas, garantizando la protección de compresores y motores en condiciones exigentes.

2025-11-05/17:44:12